Modern vehicles rely heavily on sophisticated suspension systems to deliver the smooth, controlled ride that drivers expect. These intricate mechanical assemblies work tirelessly to absorb road imperfections, maintain tyre contact with the surface, and provide the stability necessary for safe handling. Understanding how to properly maintain your suspension components can significantly extend their service life whilst ensuring optimal performance and safety. The investment in regular suspension care pays dividends through improved ride quality, enhanced vehicle control, and reduced long-term repair costs.

Suspension systems represent one of the most complex engineering challenges in automotive design, requiring precise balance between comfort and performance. Professional mechanics encounter suspension-related issues daily, with many problems stemming from inadequate maintenance rather than component failure. By implementing proper care protocols and understanding the warning signs of suspension degradation, vehicle owners can avoid costly repairs and maintain their car’s handling characteristics for years to come.

Understanding automotive suspension system components and their functions

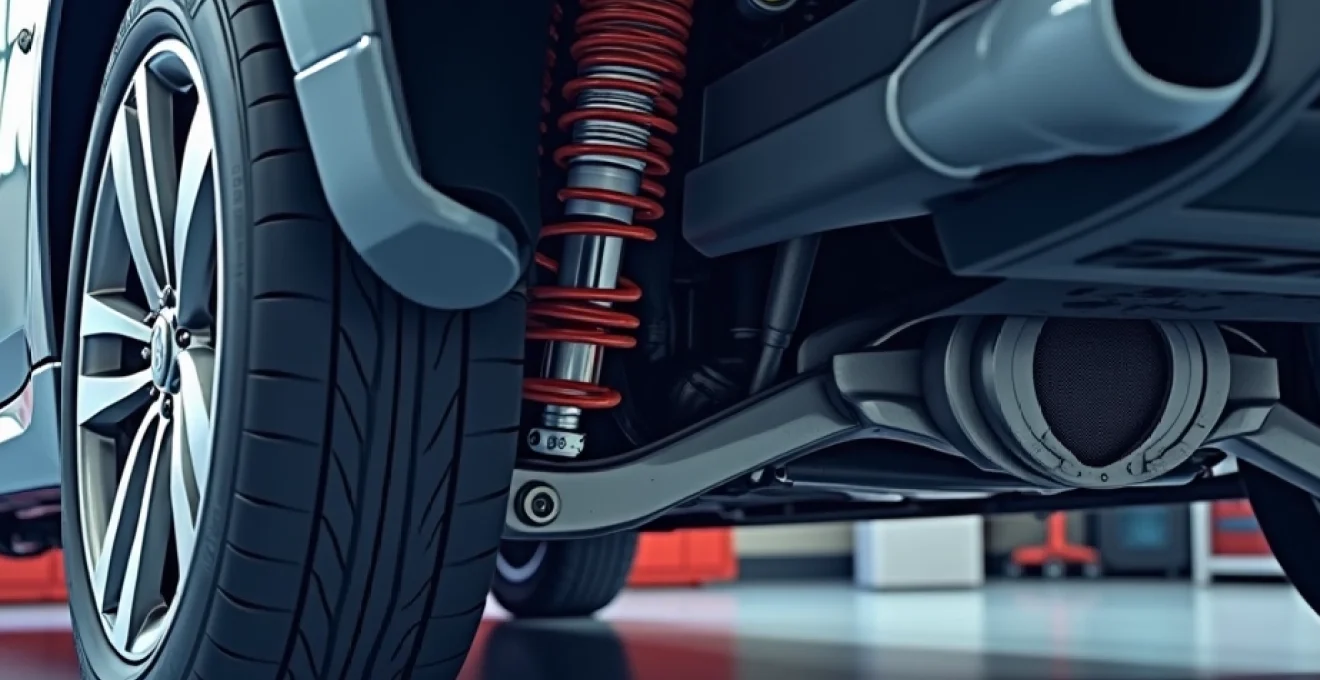

The foundation of effective suspension maintenance lies in comprehending how each component contributes to overall system performance. Modern suspension systems integrate multiple elements working in harmony to control vehicle movement, absorb road irregularities, and maintain proper wheel alignment. Springs bear the vehicle’s weight whilst absorbing impact energy, whilst dampers control the oscillations that would otherwise create an uncomfortable, bouncy ride. Control arms position the wheels correctly relative to the chassis, ensuring proper geometry during suspension travel.

Suspension systems vary dramatically between vehicle types and manufacturers, with each configuration offering distinct advantages. The choice between different suspension architectures depends on factors including vehicle weight, intended use, manufacturing cost considerations, and performance requirements. Understanding these differences helps vehicle owners appreciate why certain maintenance approaches work better for specific suspension designs.

Macpherson strut assembly construction and load distribution

MacPherson struts represent one of the most common suspension designs in modern automobiles, combining the spring and damper into a single, compact unit. This configuration simplifies manufacturing whilst reducing weight and complexity compared to separate spring-and-damper arrangements. The strut assembly bears significant loads through its mounting points, requiring robust construction to handle both vertical forces from road impacts and lateral forces during cornering.

The strut’s unique design places the damper inside a coil spring, with the entire assembly connecting directly to the wheel hub. This arrangement means that strut wear affects multiple aspects of vehicle handling simultaneously. When strut bearings deteriorate, drivers may notice increased road noise, steering wheel vibration, and reduced directional stability. Regular inspection of strut mounting points reveals early signs of wear before performance degradation becomes noticeable.

Double wishbone configuration benefits in performance vehicles

Double wishbone suspensions offer superior control over wheel movement compared to simpler designs, making them popular in performance and luxury vehicles. This configuration uses upper and lower control arms to precisely control wheel geometry throughout the suspension’s range of motion. The result is improved handling characteristics, better tyre contact during cornering, and enhanced ride quality over varying road surfaces.

Maintaining double wishbone systems requires attention to multiple pivot points and bushings. Each control arm contains several wear items that can affect handling precision. Ball joints at the outer ends of control arms experience significant stress during cornering and braking, whilst bushings at the chassis mounting points absorb vibration and allow controlled movement. Regular lubrication of grease fittings, where present, extends component life considerably.

Anti-roll bar mechanics and cornering stability enhancement

Anti-roll bars, sometimes called sway bars, play a crucial role in maintaining vehicle stability during cornering by reducing body roll. These steel bars connect the left and right sides of the suspension, transferring load between wheels when cornering forces would otherwise cause excessive body lean. The effectiveness of anti-roll bars depends on properly functioning mounting bushings and end links that connect the bar to the suspension components.

Common anti-roll bar problems include worn bushings that create knocking noises over bumps and damaged end links that reduce cornering stability. These components experience constant movement and stress, making them relatively high-maintenance items. Regular inspection of anti-roll bar components during routine servicing prevents minor issues from developing into safety-critical failures that could compromise vehicle control.

Shock absorber damping coefficients and rebound control

Shock absorbers control the speed at which suspension components move, preventing excessive oscillation that would make the vehicle difficult to control. Modern dampers use sophisticated valve systems to provide different resistance characteristics for compression and rebound movements. This allows engineers to tune the suspension response for optimal comfort and handling balance across various driving conditions.

Damper performance degrades gradually, making it difficult for drivers to notice the change in handling characteristics. Professional testing reveals that worn dampers significantly increase stopping distances and reduce vehicle stability during emergency manoeuvres. Understanding damper operation helps vehicle owners recognise when replacement becomes necessary, typically every 80,000 to 120,000 kilometres depending on driving conditions and vehicle weight.

Professional suspension inspection protocols and diagnostic techniques

Systematic inspection procedures enable early detection of suspension problems before they compromise safety or require expensive repairs. Professional technicians follow established protocols that examine each component methodically, using both visual inspection and functional testing to assess condition. These comprehensive evaluations reveal wear patterns that indicate specific problems, allowing targeted repairs rather than wholesale component replacement.

Modern diagnostic equipment enhances traditional inspection methods, providing precise measurements of suspension geometry and component condition. Computerised alignment systems detect minute changes in wheel positioning that could indicate worn components, whilst specialised tools measure ball joint play and bushing condition with remarkable accuracy. This technology-assisted approach ensures nothing is overlooked during inspection.

Visual assessment of rubber bushings and mounting points

Rubber bushings serve as vibration isolators whilst allowing controlled movement between suspension components. These elements deteriorate over time due to heat, ozone, and mechanical stress, developing cracks, splits, and excessive softness that compromise their effectiveness. Visual inspection reveals obvious damage, but subtle degradation requires tactile examination to detect loss of resilience or improper fit.

Proper bushing assessment requires removing any covering plates or shields that might obscure the rubber elements. Technicians look for signs of oil contamination, which accelerates rubber deterioration, and evidence of excessive movement that indicates worn bushing material. Environmental factors such as road salt and extreme temperatures can significantly accelerate bushing degradation in certain climates, requiring more frequent replacement intervals.

Bounce test methodology for damper performance evaluation

The traditional bounce test provides a quick assessment of damper condition by evaluating how quickly the vehicle settles after being manually compressed. Professional technicians apply downward force to each corner of the vehicle, then release it whilst counting the oscillations before the suspension stabilises. Properly functioning dampers should control movement within one complete cycle, whilst worn dampers allow multiple bounces.

Modern testing equipment provides more precise damper evaluation through electronic measurement of compression and rebound forces. These sophisticated systems detect asymmetrical damping characteristics and gradual performance degradation that might not be apparent during basic bounce testing. Such detailed analysis helps determine whether dampers require immediate replacement or can continue service for additional mileage.

Ball joint play measurement using dial indicators

Ball joints connect control arms to wheel hubs, allowing steering movement whilst maintaining structural integrity during suspension travel. These critical components develop play over time as the bearing surfaces wear, eventually compromising steering precision and potentially leading to dangerous separation failures. Accurate measurement requires proper loading of the suspension to simulate operational conditions.

Professional ball joint inspection uses dial indicators to measure movement in multiple directions whilst applying specific loads. Specifications vary between vehicle manufacturers, but excessive play in any direction indicates replacement necessity. Some modern vehicles use pressed-in ball joints that require complete control arm replacement, whilst others feature serviceable units that can be replaced individually. Understanding the specific design helps determine appropriate maintenance strategies.

Alignment parameter analysis: camber, caster, and toe specifications

Wheel alignment directly affects tyre wear patterns, handling characteristics, and suspension component longevity. Camber measures the inward or outward tilt of the wheel when viewed from the front, whilst caster refers to the forward or rearward angle of the steering axis. Toe describes whether wheels point inward or outward when viewed from above. Each parameter must fall within manufacturer specifications for optimal performance.

Modern alignment equipment provides precise measurements and adjustment capabilities that ensure optimal wheel positioning. Computerised systems detect minute deviations from specifications whilst accounting for vehicle loading and suspension wear. Regular alignment checks prevent irregular tyre wear and identify suspension problems before they require expensive repairs. Professional technicians understand how various suspension faults affect alignment parameters, using this knowledge to diagnose underlying problems.

Preventive maintenance schedules for suspension longevity

Developing a comprehensive maintenance schedule tailored to your vehicle’s suspension system significantly extends component life whilst maintaining optimal performance. Different suspension designs require varying maintenance intervals, with some components needing attention every 20,000 kilometres whilst others may last the vehicle’s lifetime under normal conditions. Understanding these requirements helps prioritise maintenance activities and budget for future needs.

Environmental conditions dramatically influence maintenance requirements, with vehicles operating in harsh climates or challenging terrain needing more frequent attention. Coastal areas with salt air, regions with extreme temperature variations, and areas with poor road surfaces all accelerate suspension wear. Similarly, driving habits affect component longevity, with aggressive driving, frequent heavy loading, and high-performance driving requiring shortened maintenance intervals.

Lubrication represents one of the most critical maintenance activities for suspension longevity, though many modern vehicles use sealed components that eliminate this requirement. Where grease fittings exist, regular lubrication prevents wear and corrosion whilst maintaining smooth operation. The lubricant type and service interval depend on the specific component design and operating environment, with some applications requiring specialty greases for optimal performance.

Component replacement schedules vary significantly between suspension elements, with wear items like bushings and ball joints typically requiring replacement every 100,000 to 150,000 kilometres under normal conditions. Dampers and struts generally last 80,000 to 120,000 kilometres, whilst springs may last the vehicle’s lifetime unless damaged by corrosion or impact. Understanding these typical lifespans helps plan maintenance budgets and avoid unexpected failures.

Proper maintenance documentation becomes invaluable for tracking component history and predicting future needs. Recording replacement dates, mileage intervals, and any symptoms noted during service helps identify patterns that might indicate specific problems or unusual wear rates. This information proves particularly valuable when dealing with warranty claims or selling the vehicle, demonstrating responsible ownership and proper care.

Common suspension failure modes and early warning indicators

Recognising early warning signs of suspension problems enables prompt intervention before minor issues escalate into safety hazards or expensive repairs. Most suspension failures develop gradually, providing ample warning through changes in vehicle behaviour, unusual noises, or abnormal wear patterns. Understanding these indicators helps vehicle owners make informed decisions about when to seek professional evaluation and potential component replacement.

Noise represents one of the earliest indicators of suspension problems, with different sounds indicating specific component failures. Clunking noises over bumps often indicate worn anti-roll bar links or damaged strut mounts, whilst creaking sounds during steering input may suggest deteriorating ball joints or control arm bushings. Squeaking noises from the front suspension during cornering frequently point to worn upper strut bearings requiring replacement.

Changes in vehicle handling characteristics provide clear evidence of suspension degradation, though drivers may gradually adapt to deteriorating conditions without recognising the problem. Increased body roll during cornering, longer stopping distances, or reduced steering precision all indicate suspension issues requiring professional evaluation. Vehicles that continue bouncing after hitting road irregularities demonstrate worn dampers that need immediate replacement.

Tyre wear patterns reveal valuable information about suspension condition and alignment status. Excessive wear on the inside or outside edges of the tyre tread indicates camber problems that could stem from worn suspension components or accident damage. Feathered wear patterns across the tread suggest toe misalignment, whilst cupping or scalloping indicates worn dampers allowing excessive wheel movement. Regular tyre rotation helps identify these patterns before they become severe.

Fluid leaks from dampers indicate internal seal failure and compromised performance, requiring prompt replacement to maintain vehicle control. Modern gas-charged dampers may not show obvious fluid leaks despite internal failure, making professional testing necessary for accurate diagnosis. Oil-stained shock absorber bodies clearly indicate replacement necessity, whilst clean units may still require testing to verify proper operation.

Professional mechanics report that approximately 60% of suspension problems could be prevented through regular inspection and prompt attention to early warning signs, emphasising the importance of proactive maintenance over reactive repairs.

Advanced suspension technologies in modern vehicles

Contemporary vehicles increasingly feature sophisticated suspension technologies that adapt to driving conditions and driver preferences in real-time. These advanced systems require specialised knowledge for proper maintenance and repair, often incorporating electronic controls, hydraulic actuators, and complex sensors that traditional mechanics may not fully understand. The complexity of these systems necessitates regular software updates and calibration procedures that extend beyond conventional maintenance practices.

Electronic suspension management systems continuously monitor vehicle behaviour and road conditions, adjusting damper characteristics thousands of times per second to optimise ride quality and handling. These systems integrate with other vehicle control systems including stability management, traction control, and active safety features to provide unprecedented levels of performance and safety. However, this integration also means that suspension problems can affect multiple vehicle systems simultaneously.

Adaptive damping systems in BMW’s EDC and Mercedes-Benz ABC

BMW’s Electronic Damper Control (EDC) and Mercedes-Benz’s Active Body Control (ABC) represent sophisticated approaches to adaptive suspension management, using different technologies to achieve similar goals. EDC systems adjust damper characteristics electronically, providing multiple driving modes that change suspension response to suit varying conditions. ABC goes further by incorporating hydraulic actuators that can actively counteract body movement during cornering and braking.

Maintaining these advanced systems requires specialised diagnostic equipment and software access that independent workshops may not possess. Sensor calibration, hydraulic fluid service, and software updates often require dealer-level equipment and training. Component costs for these systems significantly exceed traditional suspension parts, making preventive maintenance even more critical for controlling long-term ownership costs.

Air suspension calibration in range rover and audi allroad models

Air suspension systems offer exceptional ride quality and load-levelling capabilities but require more intensive maintenance than conventional spring systems. These configurations use air springs instead of steel coils, allowing height adjustment and load compensation through computer-controlled air management. Range Rover and Audi Allroad models exemplify sophisticated air suspension implementations that provide remarkable versatility across varying terrain and loading conditions.

Air suspension maintenance involves monitoring compressor operation, checking air lines for leaks, and ensuring proper height sensor calibration. The air springs themselves can develop leaks or internal damage that requires replacement, often at significant expense. Regular system diagnostics help identify developing problems before complete system failure occurs, which could leave the vehicle stranded with collapsed suspension.

Magnetic ride control technology in cadillac and ferrari applications

Magnetic Ride Control represents the pinnacle of adaptive suspension technology, using magnetorheological fluid that changes viscosity instantly when exposed to magnetic fields. This allows virtually instantaneous damper adjustment in response to road conditions and driving inputs. Cadillac pioneered this technology for luxury applications, whilst Ferrari adapted it for extreme performance use in their supercars.

The sophistication of Magnetic Ride Control systems requires specialised maintenance approaches that differ significantly from conventional dampers. The magnetorheological fluid has specific service intervals and replacement procedures, whilst the electronic control systems require regular calibration and software updates. Component replacement costs for these systems can exceed £2,000 per corner, making proper maintenance absolutely critical for controlling ownership expenses.

Professional servicing versus DIY suspension maintenance approaches

The decision between professional servicing and do-it-yourself maintenance depends heavily on the specific suspension system design, available tools, and individual mechanical expertise. Basic maintenance activities like visual inspections and bounce tests can be safely performed by knowledgeable vehicle owners, whilst alignment procedures and component replacement typically require professional equipment and training. Understanding these limitations helps vehicle owners make informed decisions about which tasks to attempt independently.

Modern suspension systems increasingly incorporate safety-critical components and complex procedures that exceed typical DIY capabilities. Compressed springs store tremendous energy that can cause serious injury if improperly handled, whilst alignment procedures require precision equipment to achieve proper specifications. Many contemporary vehicles also feature integrated electronic systems that require specialised diagnostic tools for proper service and calibration.

Professional workshops offer advantages beyond specialised equipment, including access to technical service bulletins, updated repair procedures, and warranty coverage for their work. Experienced technicians understand subtle symptoms that might escape notice during DIY inspection, potentially preventing expensive failures through early intervention. However, professional service costs continue rising, making basic DIY maintenance increasingly attractive for budget-conscious vehicle owners.

The complexity of suspension work varies dramatically between different maintenance activities, with some procedures suitable for competent DIY mechanics whilst others require professional intervention. Basic visual inspections can identify obvious problems like leaking dampers or damaged anti-roll bar links, whilst subtle issues like incipient ball joint wear may require professional

diagnosis to identify reliably. Oil changes and basic fluid level checks represent straightforward DIY activities, whilst spring replacement or electronic system calibration require professional expertise and specialised equipment.

Cost considerations play a significant role in maintenance decisions, with professional service rates often exceeding £100 per hour at authorised dealerships. Independent workshops may offer more competitive pricing whilst still providing professional-grade equipment and expertise. However, attempting complex repairs without proper knowledge or tools can result in safety hazards and expensive mistakes that ultimately cost more than professional service would have initially.

Safety represents the paramount concern when deciding between DIY and professional maintenance approaches. Suspension components operate under tremendous stress and store significant energy that can cause serious injury if mishandled. Coil springs under compression contain enough force to cause fatal injuries, whilst improper ball joint replacement procedures can result in sudden component separation during driving. Professional technicians understand these risks and employ proper safety procedures to prevent accidents.

Modern vehicles incorporate increasingly sophisticated diagnostic systems that require professional scan tools for proper maintenance and repair. These systems monitor suspension performance continuously, storing fault codes that indicate specific problems requiring attention. Without access to manufacturer diagnostic protocols, DIY mechanics cannot properly assess electronic suspension systems or perform required calibration procedures after component replacement.

The availability of quality aftermarket parts has improved significantly in recent years, offering DIY mechanics access to components that meet or exceed original equipment specifications. However, identifying the correct parts for specific vehicle applications requires detailed knowledge of suspension configurations and compatibility requirements. Professional workshops maintain comprehensive parts databases and supplier relationships that ensure proper component selection and availability.

Industry surveys indicate that approximately 40% of DIY suspension repairs require subsequent professional correction due to improper installation procedures or inadequate diagnostic assessment, highlighting the complexity of modern suspension systems.

Tool requirements for suspension work can represent a substantial investment that may not be cost-effective for occasional DIY maintenance. Professional spring compressors, ball joint presses, and alignment equipment cost thousands of pounds whilst requiring proper training for safe operation. Specialty tools for specific vehicle applications may only be available through professional tool suppliers, making them impractical for individual ownership.

Documentation and warranty considerations favour professional service for major suspension work, particularly on newer vehicles where improper maintenance could void manufacturer warranties. Professional workshops provide detailed service records and warranty coverage for their work, offering peace of mind that DIY approaches cannot match. Additionally, many insurance policies require professional maintenance records for claim validation following suspension-related accidents.

The learning curve for suspension maintenance varies considerably between different vehicle types and system configurations. Older vehicles with conventional suspension designs may offer reasonable DIY opportunities for mechanically inclined owners, whilst modern vehicles with integrated electronic systems require professional expertise. Understanding personal limitations and vehicle complexity helps determine appropriate maintenance strategies that balance cost considerations with safety requirements.

Regular professional inspection remains advisable even for vehicles receiving DIY maintenance, providing expert assessment of overall system condition and identification of developing problems that might escape notice during routine owner checks. This hybrid approach combines cost-effective owner maintenance with professional expertise where needed, optimising both safety and financial considerations. Professional technicians can also provide guidance on which maintenance activities are appropriate for DIY completion and which require professional attention.