The Nissan X‑Trail start/stop system can feel like a blessing in city traffic—right up until the day the “Start/Stop System Fault” message appears on the dash and the engine management light tags along. For many owners and independent garages, that warning turns what should be a fuel‑saving feature into a diagnostic headache. The challenge is that the fault message is only the tip of the iceberg; the real issue is buried in a web of battery management, sensors, CAN communication and software logic that must all agree before the engine is allowed to cut out and restart automatically. Understanding how the system works, which components are critical, and how to test them methodically is the key to getting a troublesome X‑Trail T31 or T32 reliably back to its intelligent start/stop behaviour.

Common start/stop system fault symptoms on nissan X‑Trail T31 and T32 models

On UK‑market Nissan X‑Trail T31 and T32 models, start/stop faults rarely appear in isolation. You typically see a combination of symptoms that, when read together, tell a story about what the control units are unhappy with. The most obvious sign is the “Start/Stop System Fault” or “Stop/Start System Fault” message in the combination meter, often accompanied by the yellow engine management light. In a fair number of 2014–2019 T32 cases, this is triggered alongside emissions‑related DTCs such as P0037 or P0138, which can confuse owners into chasing oxygen sensor issues before checking battery and charging health.

You may notice the auto stop function never activates, even after a long drive when the engine is fully warm. Others report that stop/start works once or twice, then disables for the rest of the journey, especially in slow, congested urban traffic. In some vehicles the system appears completely dead, while in others a flickering indicator light suggests intermittent sensor or wiring faults. A subtle yet very common symptom is increased starter motor engagement time during hot restarts, hinting at marginal crankshaft position sensor or battery performance long before a full failure occurs. These real‑world patterns matter more than a single warning light when approaching proper Nissan X‑Trail start/stop system fault diagnosis.

How the nissan X‑Trail intelligent start/stop system works (MR20DD, R9M, M9R engines)

The modern X‑Trail start/stop system is more than just a beefed‑up starter motor and a bigger battery. On MR20DD petrol and R9M/M9R diesel engines it operates as an integrated energy management strategy controlled by the ECM (engine control module) in cooperation with the BCM (body control module) and IPDM (Intelligent Power Distribution Module). Think of it as a small team of controllers constantly asking “Is it safe, comfortable and mechanically sensible to shut this engine off right now?”

Key start/stop components: IBS sensor, AGM battery, BCM, IPDM and ECM

The foundation of reliable start/stop operation is the correct battery and an accurate measurement of its status. Nissan specifies enhanced AGM or EFB batteries for stop/start‑equipped X‑Trail models because they tolerate frequent charge‑discharge cycles and higher starter loads. Clamped to the negative terminal is the Intelligent Battery Sensor (IBS), which measures battery voltage, current and temperature. The ECM uses this data to estimate state of charge (SOC) and state of health (SOH); if either is too low, auto stop is suppressed to protect the battery.

The BCM acts as a gateway and logic controller for many of the driver‑input signals relevant to start/stop, such as the brake pedal switch, clutch pedal position and stop/start OFF button status. The IPDM is effectively a smart fuse and relay box that distributes power and handles starter and alternator control. The ECM brings these inputs together with engine data (coolant temperature, crankshaft and camshaft synchronisation, intake air temperature, etc.) to make the final decision to permit engine shutdown and restart. If any of these modules loses trust in the others, the conservative response is to disable the system and illuminate a warning.

CAN bus communication paths between ECM, BCM, IPDM and combination meter

Communication between the ECM, BCM, IPDM and the combination meter takes place over the high‑speed CAN bus. For a successful auto stop event, the ECM needs confirmation that the brake is applied, the vehicle speed is low enough, the transmission state is appropriate, and there are no outstanding critical DTCs. Those discrete signals originate at sensors and switches, are interpreted by the BCM, and then sent as CAN messages.

The IPDM transmits information about relay states and alternator load, while the combination meter displays system status based on messages from both the ECM and BCM. An intermittent CAN fault, high resistance in a twisted pair, or a gateway configuration issue can all manifest as sporadic start/stop availability. In some UK workshops, wiring repairs near the front left wheel arch—after minor collision damage or corrosion—have restored proper communication and resolved persistent “Start/Stop System Fault” messages without replacing any major component.

Operating conditions for auto stop/auto restart in urban and motorway driving

The Nissan owners manual details a surprisingly long list of conditions under which the system will not perform an auto stop. In simple terms, the engine is allowed to stop only when the vehicle is stationary (or nearly stationary in “before vehicle halt” mode), the coolant temperature is within a calibrated window, the battery SOC is sufficient, and cabin comfort or safety are not compromised. In heavy urban driving with headlights, heated screens and air conditioning running, the system may deliberately abstain from stopping the engine to maintain electrical and thermal comfort.

On the open motorway, you might wonder why the system never activates despite perfect battery figures. In those conditions, vehicle speed and gear selection typically prevent auto stop logic from arming. The system is calibrated for low‑speed, frequent‑stop scenarios where fuel savings are significant, and that calibration is conservative. Any deviation from expected sensor readings—such as an implausible brake vacuum measurement or fluctuating coolant temperature—can disable start/stop without storing an obvious hard fault code.

Differences between manual and X‑Tronic CVT start/stop control logic

Manual X‑Trail variants and X‑Tronic CVT models share the same basic system architecture but differ in how driver intent is assessed. On manual cars, the clutch pedal position sensor is crucial. Auto stop is generally permitted when the clutch is fully depressed, the vehicle is at or below a low speed threshold, and a gear (usually neutral or first) is selected safely. Re‑start is triggered when the clutch pedal moves past a defined point, indicating intent to drive away.

On the CVT, the park/neutral position switch and brake pedal switch take over this role. The engine is allowed to stop when the selector is in D, the brake is firmly applied, and vehicle speed is near zero. Re‑start occurs when the brake is released or the accelerator is pressed. Misadjustment of the gear position switch on CVT cars, particularly after gearbox or selector work, is a known cause of start/stop inaction because the ECM never receives a clear “Drive and stationary” combination of inputs.

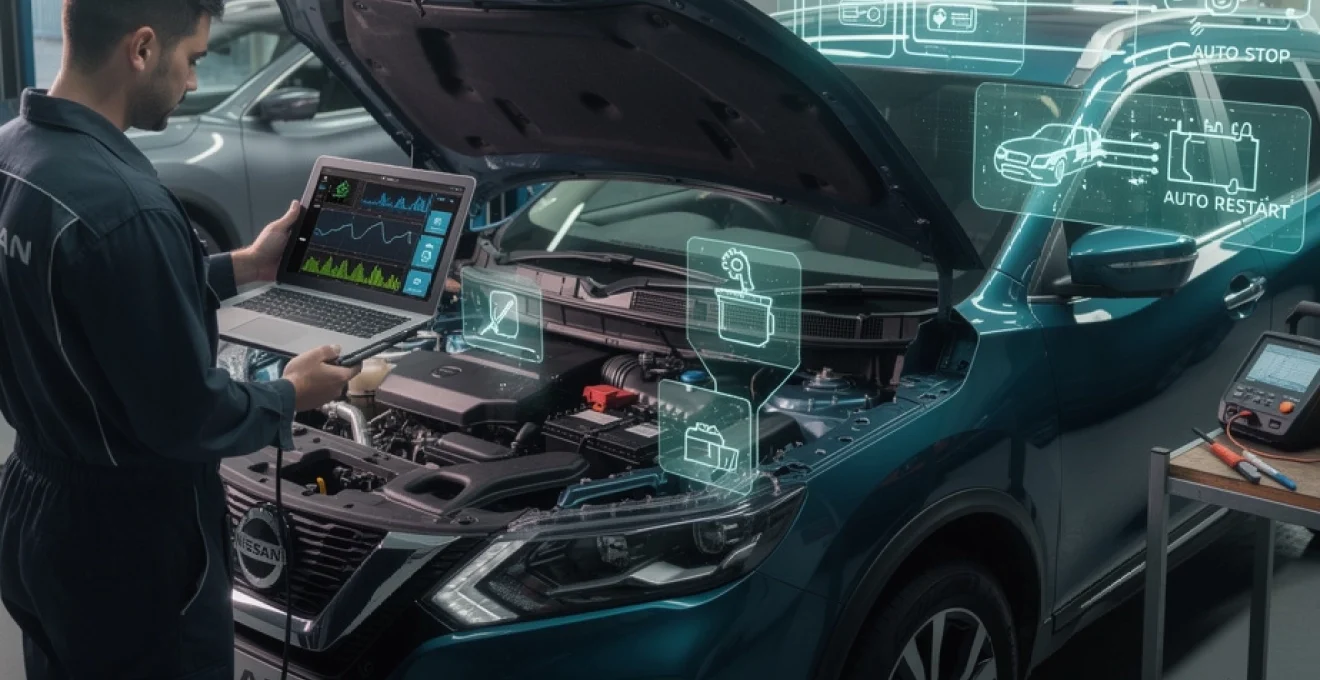

Diagnostic workflow for start/stop faults using Consult‑III plus and OBD‑II scanners

A structured diagnostic workflow prevents unnecessary parts replacement and saves considerable time, especially when dealing with intermittent Nissan X‑Trail start/stop system faults. Professional experience shows that beginning with a clear DTC scan, followed by analysis of live data and freeze frame information, gives a far better picture than jumping straight to battery swap or sensor replacement. Generic OBD‑II tools provide a useful first look, but manufacturer‑level access via Consult‑III Plus offers guided test plans and functional tests specifically for Nissan stop/start circuits.

Reading and interpreting start/stop related DTCs (e.g. P0615, P0335, B24XX) on X‑Trail

The first step is always to read and record all DTCs from the ECM, BCM, IPDM and combination meter. Start/stop issues may be associated with codes that, at first glance, appear unrelated. Typical examples include P0615 (starter relay circuit), P0335 (crankshaft position sensor circuit), B24XX‑series body and brake switch faults, and battery‑related codes. Notably, some T32 owners reporting “Stop/Start System Fault” have concurrent oxygen sensor codes (P0037, P0138), indicating that poor voltage control can impact multiple engine management circuits simultaneously.

Understanding which codes are current, which are historic, and which are pending helps prioritise testing. If a B24 series DTC for brake switch plausibility is stored alongside the start/stop fault, the brake input should be investigated before suspecting the battery. Conversely, if the only codes relate to low system voltage or starter control, focus should shift to battery condition, IBS data and charging performance. Clearing codes and seeing which ones return after a short drive can also distinguish between one‑off disturbances and persistent electrical or mechanical failures.

Live data analysis: battery SOC, IBS voltage, engine coolant temperature and brake switch status

Once DTCs are documented, attention turns to live data. A common oversight in Nissan X‑Trail start/stop diagnosis is relying purely on multimeter readings at the battery. While 12–12.5 V at rest may seem acceptable, the ECM’s calculated SOC based on IBS inputs can show a very different picture, especially on older AGM units. Monitoring live parameters such as battery SOC, IBS voltage, battery temperature, engine coolant temperature and brake switch status under different loads provides valuable clues.

Watching the brake switch live data while gently pressing and releasing the pedal will confirm whether the dual‑circuit switch is delivering consistent, timely signals. Similarly, comparing coolant temperature readings to an external thermometer can reveal a lazy or biased sensor that keeps the system in a permanent “engine still warming up” mode. Viewing these values during a real‑world drive cycle—particularly during urban stop‑start driving—is often more revealing than static tests in the workshop.

Freeze frame and snapshot data usage for intermittent start/stop malfunction

Intermittent start/stop faults are some of the most frustrating issues encountered in UK workshops, especially when the customer reports “It always happens on the school run, but never on the way to the garage.” Freeze frame and snapshot data from the ECM and BCM can bridge that gap by capturing the exact conditions at the moment a DTC was stored. These records typically include engine speed, vehicle speed, coolant temperature, battery voltage, gear position and brake/clutch input states.

By comparing multiple freeze frames for recurring DTCs, a pattern often emerges. Perhaps the fault always appears with battery voltage just under 11 V during crank, or with an implausible coolant temperature of 30 °C on a cold morning. That pattern directs targeted testing, such as a voltage drop test on starter circuits or a sensor plausibility check, instead of blindly replacing components. Technicians who regularly review snapshot data for Nissan stop/start faults tend to achieve faster, more reliable fixes.

Guided diagnostic routines with nissan Consult‑III plus vs generic tools (launch, autel)

Consult‑III Plus offers guided diagnostic routines specifically for Nissan start/stop systems, including actuator tests for starter relay, alternator loading, and IBS calibration checks. These workflows prompt the technician through step‑by‑step procedures, automatically logging measurements and suggesting next actions based on thresholds defined by Nissan engineering. In contrast, generic tools such as Launch or Autel provide broad coverage and useful live data access but may lack manufacturer‑specific routines.

For independent garages, a hybrid approach works well: use a generic scanner for quick triage and general OBD‑II code reading, then rely on Consult‑III Plus (or equivalent OEM‑level access) when the issue proves stubborn or when software updates and coding checks are needed. The difference becomes especially clear in complex cases where the fault lies in configuration, not in a clearly defective part. In those situations, only the OEM tool exposes the necessary configuration menus and calibration procedures.

When to perform ECU and BCM software updates for start/stop calibration issues

Software updates are often overlooked in mechanical‑focused workshops but have become increasingly relevant for start/stop behaviour. Nissan has released calibration updates for ECM and BCM on some X‑Trail generations to refine start/stop thresholds, improve hot restart stability and address specific drivability complaints. As emissions and fuel economy regulations evolve, so do the strategies encoded in these modules.

Updates should be considered when: the vehicle shows no hardware faults, all inputs are plausible, yet the start/stop logic behaves inconsistently; when technical service bulletins (TSBs) reference known issues for that VIN; or after major component replacement such as engine, gearbox or IPDM. The golden rule is simple: if every test says the system is healthy but the behaviour feels erratic or out of sync with Nissan’s own description in the owners manual, checking for available software updates is a rational next step.

Electrical and battery-related causes of nissan X‑Trail start/stop malfunction

Across hundreds of real‑world cases, electrical and battery‑related issues remain the number one cause of Nissan X‑Trail start/stop malfunction. Studies from European roadside assistance providers suggest that more than 60% of start/stop complaints in vehicles over five years old can be traced to marginal batteries or charging systems rather than defective sensors. That aligns with UK workshop experience: even when a battery passes a quick voltage test, its dynamic behaviour under load often tells a different story.

AGM EFB battery degradation, incorrect battery type and low SOC conditions

Start/stop‑equipped X‑Trails require AGM or EFB batteries with higher cycle life and specific internal resistance characteristics. Fitting a cheaper flooded lead‑acid unit may crank the engine, but the IBS and ECM detect abnormal voltage sag and reduced reserve capacity, leading to suppressed auto stop and regular “Start/Stop System Fault” messages. Even the correct type battery degrades over time; by year five or six, measured capacity can drop to 60–70% of original, significantly reducing SOC margin after repeated stop/start events.

Short urban journeys with high electrical loads accelerate this process. If you mainly drive three‑mile trips with lights, heated screens and climate control on, the alternator rarely has a chance to fully recharge the battery. The ECM calculates SOC and, below a defined threshold (often around 75–80% for start/stop authorisation), simply refuses to stop the engine. Charging the battery fully and then performing an IBS reset can temporarily restore function, but in many cases a high‑quality AGM replacement is the only robust solution.

Intelligent battery sensor (IBS) failures and wiring loom corrosion at the negative terminal

The IBS mounted on the negative terminal is a small but vital component. It combines a current shunt with temperature sensing and a small microcontroller that communicates with the ECM. Failures can be hard faults—no communication, implausible readings—or soft ones, where measurements drift over time due to heat or moisture ingress. Wiring surrounding the battery, especially in climates with heavy road salt use, is prone to corrosion, increasing resistance and distorting the IBS signal.

Testing should include not just voltage readings but also a close inspection of the IBS connector, harness and ground points. A voltage drop test between battery negative and chassis under a heavy load (such as cranking) can highlight poor earth paths that would otherwise mislead the SOC estimation. In several UK T32 cases, simply cleaning the negative terminal area, renewing an earth strap and reseating the IBS connector returned accurate readings and revived a previously inoperative start/stop system.

Alternator output tests, ripple voltage and charging system diagnostics

An alternator that appears to charge correctly at idle can still cause start/stop problems if its output is inconsistent under load or at higher engine speeds. Testing should involve measuring charging voltage at the battery across a range of RPMs, with and without significant electrical loads. A healthy system on an X‑Trail typically maintains around 14.2–14.8 V under most conditions, with minor fluctuations as the ECM modulates alternator demand for efficiency.

Ripple voltage, measured on an oscilloscope or sensitive multimeter, indicates the health of the alternator’s diode pack. Excessive ripple (above about 0.5 V peak‑to‑peak) can upset ECM and IBS readings, leading to spurious DTCs and unstable SOC calculation. In independent specialist experience, alternator‑related issues account for roughly 10–15% of stubborn start/stop complaints, particularly on high‑mileage diesels that have seen frequent towing or heavy electrical accessory use.

Parasitic drain testing with multimeter and clamp meter on parked X‑Trail

Parasitic current draw—electrical load on the battery with the ignition off—can silently sabotage start/stop performance by gradually pulling SOC down overnight. Modern vehicles with connected services and aftermarket accessories are particularly prone to this. Acceptable quiescent current on a Nissan X‑Trail, after all modules have gone to sleep, typically lies between 30 and 60 mA. Anything consistently above 100 mA warrants investigation.

Testing is best done with a clamp meter around the negative cable or an inline multimeter, observing current as modules shut down over 20–40 minutes. Pulling fuses methodically to see which circuit causes current to drop helps identify the culprit, whether that is a telematics unit, radio, trailer module or even a faulty door switch. Once parasitic drain is addressed, the battery can retain enough charge for reliable start/stop function between journeys.

Sensor, switch and actuator faults affecting X‑Trail start/stop operation

When the battery and charging system check out, attention naturally turns to the network of sensors, switches and actuators that inform the Nissan X‑Trail start/stop logic. Just one misreporting input can veto the entire process. Because the system is designed with a strong safety bias, many faults result in outright deactivation of auto stop rather than sporadic half‑operation. The key is to understand which inputs are critical and how to verify them objectively.

Brake pedal switch misadjustment and dual-circuit switch failure

The brake pedal switch on X‑Trail models is a dual‑circuit device, often with separate contacts for brake light activation and ECU input. If adjustment is off by even a small margin, the brake lights may work normally while the ECM never receives a valid “brake applied” signal required for start/stop engagement. Conversely, a sticking or bouncing switch can cause brief drops in the signal that the ECM interprets as the driver lifting off the brake, prompting unnecessary engine restarts.

Diagnosis involves more than watching the brake lights. Live data in the ECM or BCM should be monitored as the pedal is pressed slowly through its full travel. Both circuits should show clean, reproducible transitions at the expected pedal position, without flicker. In practice, replacement rather than cleaning is often the most reliable fix on older switches, given their low cost relative to diagnostic labour time.

Clutch pedal position sensor (manual) and park/neutral position switch (CVT) defects

For manual X‑Trails, the clutch pedal position sensor informs the ECM when the driver has disengaged the engine, allowing auto stop and determining the correct point for auto restart. If this sensor drifts or fails, the ECM never sees a stable “clutch fully depressed” signal, so it refuses to cut the engine. Symptoms can include a perceived delay in restart or the need to press the pedal unusually hard to trigger engine start.

On CVT models, the park/neutral position switch plays a similar role by indicating that the selector is in D and the vehicle is safe to stop. Wear, contamination or misalignment of this switch can lead to ambiguous states—neither fully in D nor clearly in another position—as far as the ECM is concerned. Functional tests include observing live data while moving the selector slowly between positions and checking for any jumps, dead zones or inconsistent readings.

Engine coolant temperature sensor and intake air temperature sensor plausibility checks

The ECM uses engine coolant temperature (ECT) and intake air temperature (IAT) values to judge engine warm‑up status and environmental conditions. If the ECT sensor reads too low, the system may act as if the engine is perpetually cold, delaying or disabling auto stop. Conversely, a sensor that reads excessively high may trigger cooling‑fan strategies and again lock out start/stop to protect components. IAT that is far out of line with ambient also raises suspicion of wiring or sensor faults.

Plausibility checks compare ECT and IAT readings to real‑world measurements: for example, both should be close to ambient temperature on a cold start, and ECT should rise steadily with engine running. Any sudden jumps, plateaus or reversed behaviour suggest sensor or wiring issues. On some M9R diesels, a failing ECT has been linked with both poor fuel economy and absence of auto stop, even before a specific DTC is stored.

Crankshaft position sensor and camshaft position sensor signal loss during hot restarts

Hot restart problems are often misattributed to fuel system or turbocharger faults, but on X‑Trail models with start/stop, marginal crankshaft position sensor (CKP) and camshaft position sensor (CMP) signals are a frequent cause. Heat‑soaked sensors can momentarily drop signal or produce noisy waveforms, confusing the ECM during rapid stop/start cycles in traffic. The engine may crank longer than normal, fail to restart promptly, or log codes such as P0335 while disabling auto stop until the next key cycle.

Oscilloscope testing of CKP and CMP during both cold and hot cranking is the gold standard, revealing any distortion that a simple resistance test would miss. Replacement with high‑quality, OE‑spec sensors, combined with a check of ECM earth points, has resolved many stubborn hot restart and start/stop complaints on older T31 and early T32 diesels.

Software, coding and configuration issues after battery replacement or ECU work

Electrical and sensor integrity form the mechanical backbone of the start/stop system, but configuration and coding provide the brain. After battery replacement, ECU cloning, BCM changes or module swaps, misconfigured software can leave an otherwise healthy Nissan X‑Trail with a permanently disabled start/stop function. Unlike a flat battery or a failed switch, these issues can be invisible to basic OBD‑II tools and only reveal themselves through detailed configuration checks.

Battery replacement procedures and IBS reset on nissan X‑Trail start/stop systems

Replacing the battery on a start/stop‑equipped X‑Trail is not just a matter of swapping like for like. The ECM relies on long‑term IBS data to estimate battery age and SOH. After installing a new battery, the IBS and ECM need to be reset or informed of the new unit so they can recalculate SOC and adjust charging strategies. Without that reset, the ECM may continue to behave as if the old, tired battery is still in place, suppressing auto stop and generating misleading low‑voltage DTCs.

Proper procedure typically involves fitting the correct spec AGM or EFB battery, maintaining supply voltage during the change where possible to avoid module memory loss, then using Consult‑III Plus or a capable aftermarket tool to perform a battery registration or IBS reset. Some technicians also recommend a controlled recharging cycle and road test to allow the ECM to populate new adaptation values more quickly, especially on vehicles that have been run with a weak battery for an extended period.

ECM and BCM coding errors after ECU cloning or used module installation

With the rising cost of new modules, ECU and BCM cloning or used module installation is increasingly common, particularly on older X‑Trail T31 examples. However, small mismatches in coding or configuration data between donor and recipient vehicles can have unintended side effects. Start/stop configuration flags, transmission type settings, regional variants and emission level coding all influence how—and whether—the system activates.

Symptoms may include a system that appears entirely absent (no start/stop indicator, no messages), or one that reports a permanent fault despite healthy hardware. Comparing the configuration of the suspect module to Nissan reference data, or to a known‑good vehicle of the same specification, is essential. In some instances, re‑flashing the module with the correct software image for the VIN has restored full start/stop operation without replacing any physical components.

Start/stop function deactivation via coding and how to verify configuration parameters

A lesser‑known complication arises from intentional start/stop deactivation via coding. Some owners dislike auto stop and ask tuners or coding specialists to disable it, either by adjusting configuration bits or through plug‑in modules. When the vehicle later changes hands, the new owner may be unaware that the system has been turned off by design and presents it as a fault. Distinguishing between true malfunction and coded deactivation is a vital diagnostic step.

Verification involves accessing configuration menus in the BCM and ECM and checking that start/stop is enabled for the vehicle’s market and equipment level. Any discrepancy between the hardware present (for example, an AGM battery and IBS installed) and software settings (start/stop set to “not present”) should be corrected. After re‑enabling the function, a battery registration and adaptation period may be necessary before the system behaves according to the owners manual description in all driving conditions.

Case studies: diagnosing real-world nissan X‑Trail start/stop faults in UK workshops

Theory and wiring diagrams provide a foundation, but real‑world case studies often highlight how multiple small faults combine to produce a persistent “Start/Stop System Fault” on Nissan X‑Trail models. These examples mirror situations UK garages encounter weekly and demonstrate how a logical, data‑driven approach leads to durable fixes rather than repeated parts darts. They also underline a consistent pattern: start with battery and charging, then dig into inputs, configuration and software only when the basics are proven sound.

2015 X‑Trail T32 1.6 dci with intermittent “Start/Stop system fault” message under 20 mph

A 2015 T32 1.6 dCi arrived with a complaint that the “Stop/Start System Fault” message appeared sporadically in slow traffic, usually below 20 mph, and the engine management light would occasionally accompany it. The owner had already checked the battery with a multimeter and found a resting voltage around 12.3 V, assuming this ruled out a battery issue. Generic OBD‑II scanning revealed P0037 and P0138 codes related to the oxygen sensor heater circuit and high sensor voltage, raising fears of an expensive exhaust sensor replacement.

Using Consult‑III Plus, the technician noted that battery SOC was reported at just 65% after an overnight rest and IBS data showed occasional voltage dips below 11 V during cranking. Freeze frame for the O2 sensor codes coincided with those low‑voltage cranking events. A battery conductance test revealed significant capacity loss on the original stop/start Panasonic battery. After fitting a correct‑spec AGM replacement, performing an IBS reset and clearing codes, the start/stop system behaved normally over several weeks of mixed driving. The oxygen sensor codes did not return, confirming that the root cause was marginal supply voltage rather than sensor failure.

2018 X‑Trail 1.3 DIG‑T CVT with permanent start/stop disable after aftermarket battery fitment

A 2018 X‑Trail 1.3 DIG‑T with X‑Tronic CVT was presented with a permanently disabled start/stop function following a recent battery change at a fast‑fit centre. The start/stop indicator remained off, no auto stop ever occurred, yet no clear DTCs were stored in the ECM. The new battery was a standard flooded lead‑acid unit of the correct size but not of AGM or EFB type. The customer had been told that “a battery is a battery” and that stop/start should not care.

Detailed live data inspection showed unstable IBS readings during normal driving, with voltage sagging more than 1.5 V when the alternator was briefly unloaded by the ECM. The system’s internal diagnostics quietly disabled start/stop due to poor battery performance but did not flag a conventional fault. The remedy involved installing a suitable AGM battery, registering it via Consult‑III Plus, and clearing any learned adaptation data related to the previous, incorrect battery. Within a few urban cycles, auto stop returned reliably and the customer noted smoother, quicker restarts, demonstrating how critical proper battery specification and reset procedures are on late‑model X‑Trails.

2014 X‑Trail T31 2.0 dci hot restart issue traced to crank sensor and ECM earth fault

A higher‑mileage 2014 T31 2.0 dCi came in with a complaint of unreliable hot restarts after long motorway runs. The driver reported that, in stop‑go traffic, the engine would occasionally crank for several seconds before firing, or fail to restart entirely until the ignition was cycled again. Start/stop had stopped working months earlier, but the owner had assumed this was “just the battery getting old” and carried on driving. Generic code reading revealed intermittent P0335 crankshaft position sensor faults with no specific start/stop DTCs.

Oscilloscope traces on the hot engine showed noise and dropout in the CKP signal, especially when cranking after a brief heat soak. Additionally, voltage drop testing between ECM ground and battery negative highlighted nearly 0.5 V under load, indicating a high‑resistance earth. The repair consisted of replacing the crankshaft position sensor with an OE‑quality part and cleaning/resecuring all ECM and chassis earth points. After this work, hot restarts became instant and the start/stop system gradually re‑enabled itself over the next few journeys as the ECM regained confidence in reliable restart capability, illustrating how engine management faults and ground integrity can directly impact perceived stop/start reliability.